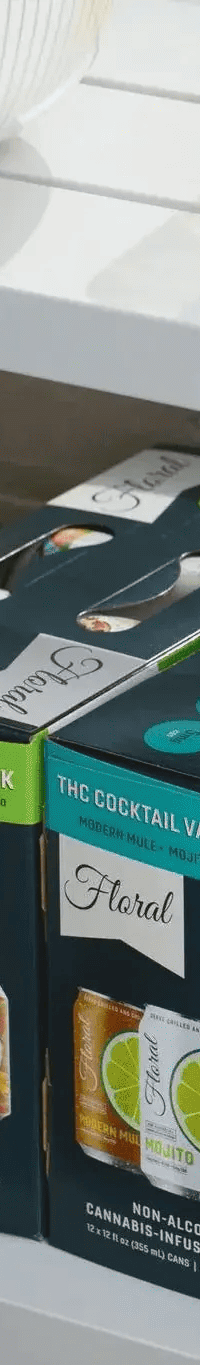

12-Can 10mg Cocktail Variety Pack

Pairs well great with:

Description

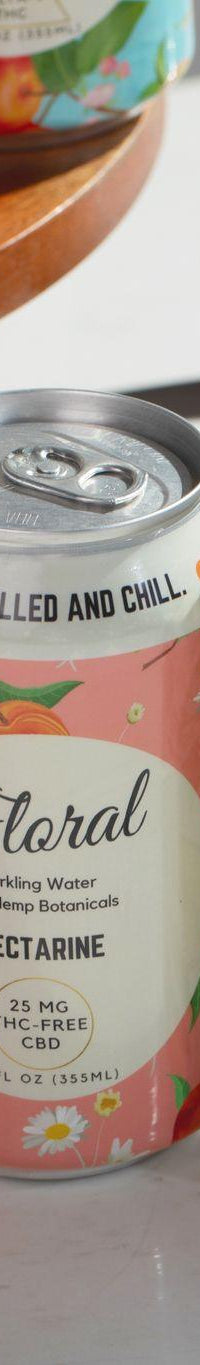

We released the 10mg THC cocktail variety pack because of numerous requests from our higher tolerance consumers. Our 12-can cocktail variety pack features three unique flavors, perfect for storing in your fridge or sharing with friends at your next gathering.

Each can offers a social experience for higher tolerance consumers. Floral's cocktails are low in calories and avoid the hangover associated with alcohol, making it a great option for a night out.

Please note that this delicious beverage is intended for adults 21+ and may provide a mild buzz. As always, please enjoy responsibly and be aware that these drinks are not suitable for those subject to drug testing.